AcoustiX Panels

CDS RECYCLED PET PANELS

WHAT ARE THE CDS ACOUSTIX PANELS?

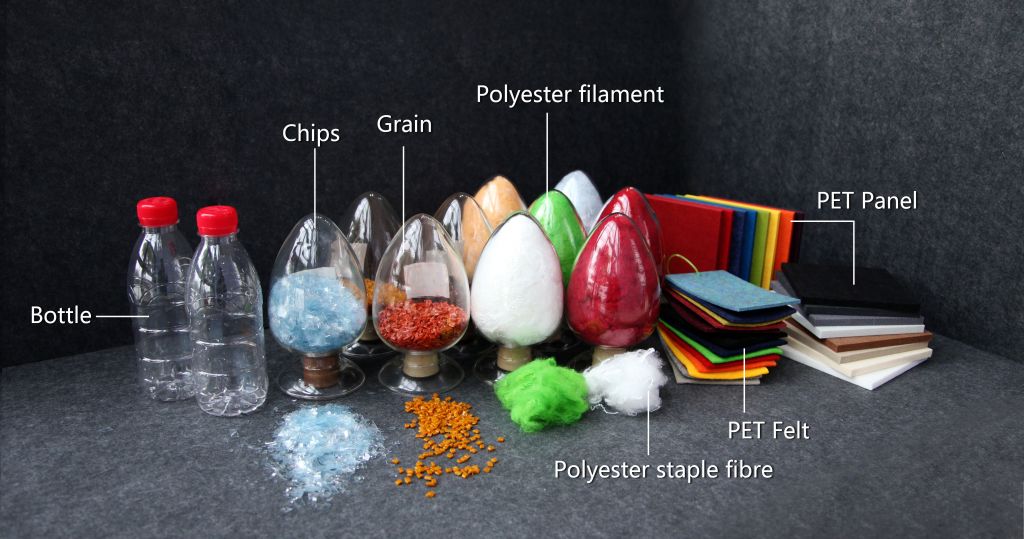

The PET fibre panel is made up of 50% recycled raw polyester fibre and is 100% recyclable at the end of this incarnation.

The polyester fibre is obtained from collected, used drinking and detergent bottles identified as PET and being recyclable.They are cleaned, sanitised and chopped up in to chips which are then fed in to a hopper.

It is heated to form a resinous substance and then extruded through thin needles to form fine fibres. These get meshed together by being cooled down and compressed, forming a webbed material.

This material is cut into boards to form panels that have a minimum life expectancy of 10 years and have excellent acoustic and insulation properties. At the end of this productive use, the product is 100% recyclable.

FIBRE INSULATION

Polyester fibre is the most popular residential insulating material in businesses today. The product is usually applied as batts of insulation pressed and moulded between the interior and exterior walls.

HEALTH

Polyester fibre is healthier and safer for the occupants as well as the installers as it does not contain any petrochemicals in the resin, no form of formaldehyde which releases gas over time and does not release small glass fibres that can cause cancer or any other health related problems.

It is a combined solution for acoustic performance, insulation and visual display as one elegant product.

WHERE ARE THE PANELS USED?

The panels can be placed anywhere to add to the environments design or added as a focal point. Some examples where the boards have been used are viewing booths, hotels, clubs, multifunction halls, conference rooms, gyms, phone booths, cinemas, libraries, recording studios, monitoring rooms, and factory offices.

Application in all industry environments are endless.

The product is able to be manufactured in a variety of colours and patterns, this includes 3D patterns and designs. With its easy-cutting abilities laser cut designs can be applied to allow the insulation board to add to the design of the environment.

The material is good for sound-absorption and insulation. It has the following properties:

![]()